|

Below is an overview of the several titanium alloys and grades which Titanium Engineers utilizes to build machined components, including Titanium Grade 2, Titanium Grade 5, Titanium 6246 (6-2-4-6) and Titanium Grade 19, more commonly known as Titanium Beta-C.

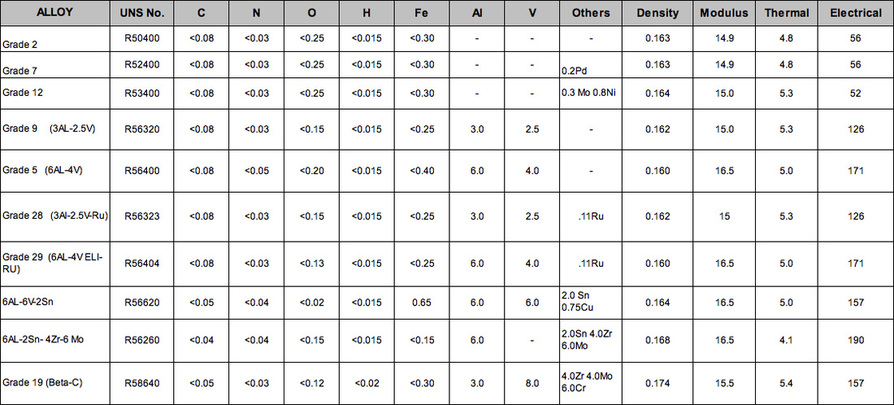

Titanium Grade 2 Titanium Grade 2 is an unalloyed titanium and what is considered a “commercially pure” titanium. Titanium Grade 2 is used commonly in applications that require welding because of its strong weldability properties. Titanium Grade 2 is light weight and highly corrosion resistant, but has much lower strength than alpha-beta or beta titanium alloys. Titanium Engineers produces titanium bar, seamless tube and titanium machined components in Titanium Grade 2. Titanium Grade 5 Titanium Grade 5 is the most commonly used Titanium worldwide and is the most commonly used alloy in the oilfield. Titanium Grade 5 is an alloyed titanium and is considered to be an alpha-beta alloy. Titanium Grade 5 is alloyed with 6% Aluminum and 4% Vanadium and is commonly known as Ti 6Al-4V. Titanium Engineers produces titanium bar, seamless tube and titanium machined components in Titanium Grade 5. Learn more about Titanium Engineers’ Heat Treat Process. Titanium 6246 (6-2-4-6) Titanium 6246 (6-2-4-6) is used in high strength applications, applications requiring materials that meet NACE MR0175/ISO 15156 and applications requiring more strength than TI Grade 5 (Ti 6Al-4V). Titanium 6246 (6-2-4-6) is an alpha-beta alloy. It has better response than Ti Grade 5 when heat treating to high strength levels. Titanium Engineers provides Ti 6246 (6-2-4-6) in titanium bar or titanium tube form, or as machined components. Learn more about Ti 6246 (6-2-4-6). Titanium Beta-C (Titanium Grade 19) Titanium Beta-C, or Ti Beta-C, is used in high strength applications, applications requiring materials that meet NACE MR0175/ISO 15156 and applications requiring more strength than TI Grade 5 (Ti 6Al-4V) or Ti 6246 (6-2-4-6) Titanium Beta-C is a Beta alloy; Beta alloys are the smallest group of titanium alloys and have good hardenability and can be heat treated to high yield strengths. Titanium Engineers produces titanium bar, seamless tube and titanium machined components in Titanium Grade 19 or Titanium Beta-C. Additional physical information on select titanium alloy grades are shown in the chart below and include Grade 2, Grade 7, Grade 12, Grade 9 (3AL-2.5V), Grade 5 (6AL-4V), Grade 28 (3Al-2.5V-Ru), Grade 29 (6AL-4V ELI-RU), 6AL-6V-2Sn, 6AL-2Sn-4Zr-6 Mo and Grade 19 (Beta-C). |

|

Titanium Engineers, Inc.

P.O. Box 1527 Stafford, TX 77497 PHONE: 281.265.2910 FAX: 281.265.2818 EMAIL: [email protected] |

Titanium Engineers AS

Regus Stavanger City Centre Verksgata 1A, 5th floor 4013 Stavanger Norway PHONE: (+47) 51 22 38 40 EMAIL: [email protected] |

Titanium Engineers Ltd

Unit 1, Coleshill Trade Park Station Road, Coleshill Birmingham B46 1AT, UK PHONE: +44 (0)1675 464200 EMAIL: [email protected] Privacy Policy |