|

Many alloys, including some titanium alloys, do not have the optimal properties in their processed condition. Heat Treatment is a process whereby controlled heating and cooling of metals is performed under very precise environmental conditions in order to alter the physical or mechanical characteristics of the metal without changing the product’s shape. If heat treatment is not done correctly, the metal may not achieve the desired properties needed to meet the engineers design specification.

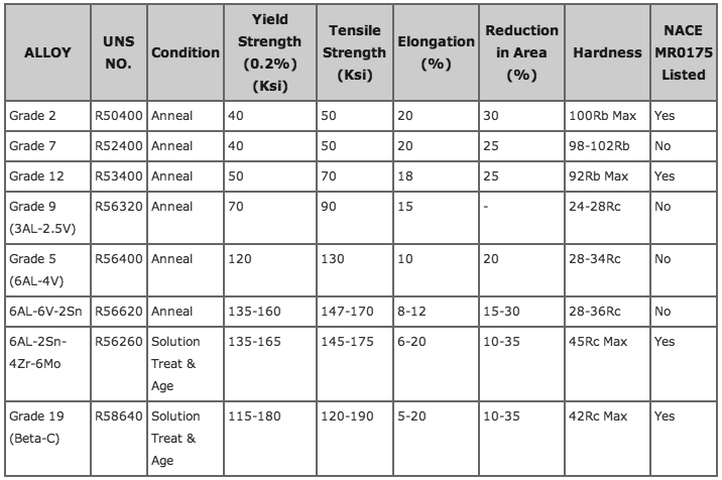

Heat Treatment is typically associated with increasing the strength of material, but it also is frequently used to improve machinability, improve formability, increase ductility or increase corrosion resistance. Therefore, it is a critical process that ensures that the specified characteristics of the metal are achieved. Titanium alloys rely on controlled heat treating to insure that proper mechanical and physical properties are achieved, but also to ensure that the material can be machined into components that have dimensional stability without reduced life. Titanium Engineers has over 25 years’ of experience processing titanium and other high-alloys. Our metallurgical background enables us to customize the heat treat cycle to produce optimum mechanical properties of our materials to meet the most demanding specifications. Mechanical Properties (minimum values) |

|

1minimum values

|

Titanium Engineers, Inc.

P.O. Box 1527 Stafford, TX 77497 PHONE: 281.265.2910 FAX: 281.265.2818 EMAIL: contactus@titaniumengineers.com |

Titanium Engineers AS

Regus Stavanger City Centre Verksgata 1A, 5th floor 4013 Stavanger Norway PHONE: (+47) 51 22 38 40 EMAIL: contactus-NO@titaniumengineers.com |

Titanium Engineers Ltd

Unit 1, Coleshill Trade Park Station Road, Coleshill Birmingham B46 1AT, UK PHONE: +44 (0)1675 464200 EMAIL: contactus-UK@titaniumengineers.com Privacy Policy |